When PCB space becomes your constraint, every millimeter matters. Engineers often face a difficult trade-off: either reduce functionality or compromise performance by downgrading passive components.

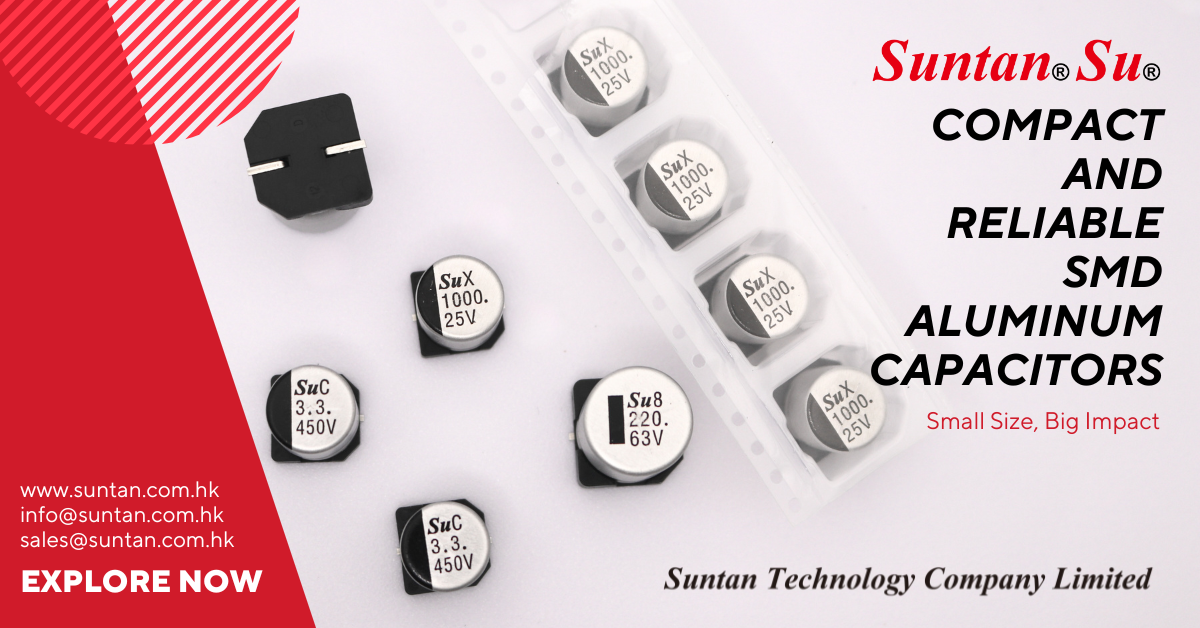

Suntan’s TS13C Series SMD Aluminum Electrolytic Capacitors solves this dilemma — offering a space-efficient design without sacrificing endurance, voltage tolerance, or manufacturing flexibility.

1. Built for Compact Boards — Without Functional Trade-offs

Unlike conventional bulky capacitors that dictate layout constraints, TS13C is designed with 12.5–16mm SMD case sizes, making it ideal for:

• 2-layer or compact 4-layer PCBs: Ideal for space-constrained circuit layouts.

• Power modules with isolated channels: Allows clean and organized power section routing.

• Height and clearance sensitive designs: Suitable for LED drivers, motor controllers, and compact enclosures.

Note: You don’t need to sacrifice output stage stability just to fit a smaller board.

2. Consolidate Functions, Not Just Footprint

Using TS13C often allows you to consolidate multiple filtering stages into a single high-performance capacitor, thanks to its:

• Voltage rating: 160V – 450V

• Capacitance range: 3.3μF – 68μF

• Ripple current rating: Up to 320mA (120Hz @ 105°C)

This means fewer components, simpler routing, and lower BOM cost — without compromising reliability.

Case study: A power engineer reduced capacitor count from 3 to 1 in a 250W PSU design using TS13C and still passed EMC testing.

3. Increase Thermal Headroom Where It Matters

Designs in confined enclosures or with limited airflow can easily push capacitors beyond their safe operating limits. TS13C is rated for:

• Operating temperature: Up to +125°C

• Load life: 5,000 hours at 105°C

• Soldering compatibility: Fully compliant with reflow and SMT automation processes

This gives your circuit more thermal margin in high-density designs — essential in LED drivers, inverter boards, or IoT controllers.

Engineering insight: Less thermal drift = more predictable performance across product lifetime.

4. Reduce Rework & Assembly Time

Because TS13C is fully compatible with SMT pick-and-place and reflow processes, it:

• Eliminates hand soldering: No need for legacy radial capacitor processes.

• Minimizes handling damage: Supports higher first-pass yield in automated lines.

• Improves production efficiency: Saves time and cost in large batch assembly.

Benefit: For EMS providers, this can mean minutes saved per unit and thousands saved per batch.

5. Application-Focused Selection Support

You don’t need to navigate capacitor charts alone. Suntan offers:

• Pre-tested solutions: Ready options for AC-DC modules, LED boards, and industrial controllers.

• Detailed documentation: ESR, ripple, and impedance data included in every

Product page:

https://www.suntan.com.hk/Aluminum-Electrolytic-Capacitors/SMD.html

Contact us:

sales@suntan.com.hk